In the early 1920s, William Beardmore & Company Ltd. began to design a series of high-power, low speed, direct-drive aircraft engines. From this line of engines and the company’s experience with diesel locomotive engines, Beardmore experimented with diesel aircraft engines. One of these engines was the compression ignition Typhoon. Designed by Alan Chorlton, the Typhoon was an inverted, water-cooled, straight-six engine with a 8.625 in (219 mm) bore and a 12 in (305 mm) stroke, giving it a total displacement of 4,207 cu in (68.9 L). In 1924, the British Air Ministry ordered compression ignition Typhoons to be used in the hydrogen-filled R100 and R101 airships. This decision was largely influenced by the fact that diesel (a low volatility fuel) did not have the quick ignition tendencies of normal fuel, thus reducing the fire risk.

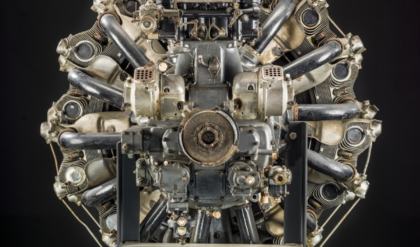

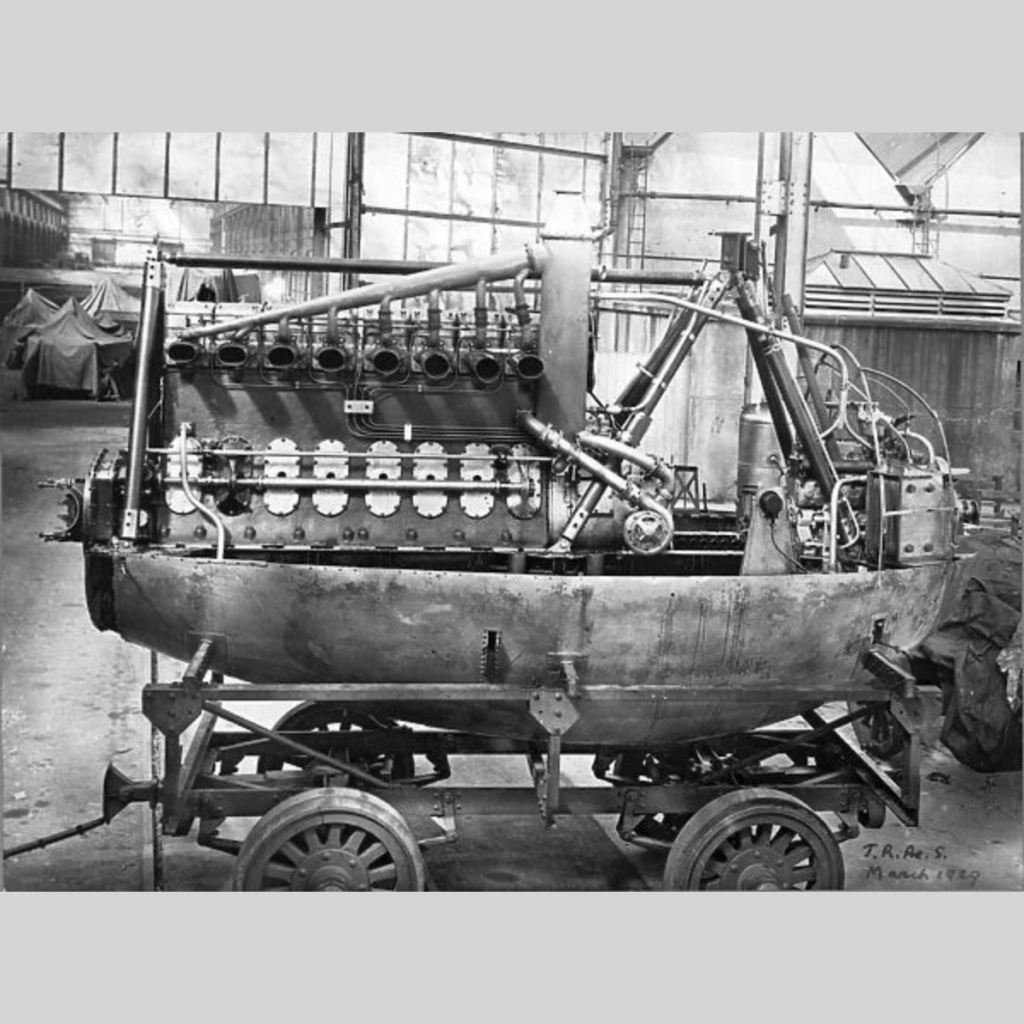

The Beardmore Tornado Mark I engine. Note the circular intake ports and access covers on the crankcase.

The R100 and R101 airships were part of the British Imperial Airship Scheme: a plan to improve communication with the far corners of the British Empire by establishing air routes. Both the R100 and R101 had a gas bag volume of over 5,100,000 cu ft (144,416 cu m), were over 710 ft (216 m) long, and had a maximum diameter of around 132 ft (40 m). The R100 was to be mostly designed and built by private industry using existing technology, while the R101 was to be designed and built by the government using experimental technology. After tests, the best aspects of both airships would be incorporated into later airships.

By 1926, with the airships under construction, the Air Ministry felt the Typhoon had reached its development potential. Beardmore offered a new Chorlton-designed six-cylinder engine that used steam-cooling and was not inverted. This engine was known as the Hurricane, but there was concern that it would not be powerful enough. Chorlton modified the Hurricane’s design by adding two additional cylinders. This engine was known as the Tornado and was expected to produce 700 hp (522 kW) at 1,000 rpm and 720 hp (537 kW) at the engine’s maximum rpm of 1,100. The Air Ministry ordered five Tornado engines for use on the R101, plus one additional engine as a spare. Tornado engines were also to be used on the R100. However, the R100 switched to standard fuel engines (Rolls-Royce Condors) because of developmental delays with the Tornado.

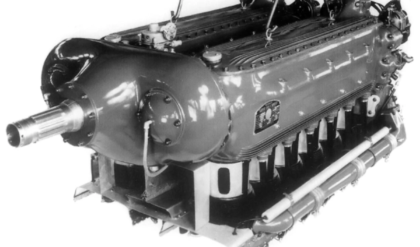

Sectional view of the Beardmore Tornado Mk III. Note the two plain main bearings that sandwiched double Michell thrust bearings on the propeller shaft.

The Beardmore Tornado was a straight, eight-cylinder engine with a 8.25 in (210 mm) bore and 12 in (304 mm) stroke, giving a total displacement of 5,132 cu in (84.1 L). The engine’s compression ratio was 12.25 to 1. Each cylinder had its own aluminum-alloy head with two intake and two exhaust valves. The valves were actuated by rockers and short pushrods from a single camshaft that ran along the side of the engine, just below the head. One fuel injector for each cylinder was placed in the center of the head, between the valves. The fuel pump was positioned at the rear of the engine along with the water pump, oil pumps, and other accessories.

The Tornado utilized steam cooling. Water in the engine was allowed to boil; the steam was then condensed in radiators attached to the airship’s hull and circulated back into the engine. For starting, a decompressor opened one inlet valve to allow the engine to be spun over and primed. A 40 hp (30 kW) starting motor was used to start the Tornado through a 20 to 1 reduction.

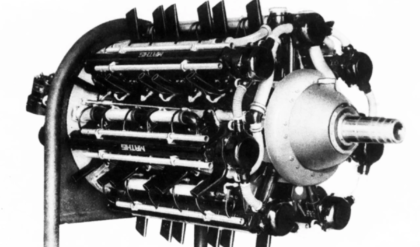

During testing, the Tornado was revised three times (Mark I, II, and III) in an attempt to cure various issues, including problems with torsional vibrations. The crankcase / cylinder block was of monobloc construction and cast in aluminum for the Mark I engine. The aluminum did not have sufficient strength, and cast iron was used, adding substantially to the engine’s weight. The cylinder heads were prone to cracking until heads specially made in Switzerland of cast steel resolved the issue. A series of large access holes with aluminum covers were provided along the crankcase. An aluminum sump was bolted to the bottom of the crankcase. With the steel crankcase, the Tornado Mark III had a dry weight of 4,200 lb (1,905 kg)—much heavier than the 3,000 lb (1,361 kg) of the Mark I engine.

Beardmore Tornado Mk III engine. Note how the access covers are now oblong. No doubt the access holes were enlarged to help offset some of the weight of the cast steel crankcase.

The vibration issues of the Tornado were exacerbated by the long crankshaft. Effort was undertaken to strengthen the crankshaft by increasing the ten (two were at the propeller end) main journals from 5 in (127 mm) in diameter to 5.75 in (146 mm) in diameter. In addition, the crankshaft webs were increased to 8.5 in (216 mm). The Crankpins remained at 4.25 in (108 mm) in diameter. Other work to dampen vibrations included adding a flywheel to the rear of the engine and a spring coupling between the crankshaft and propeller. However, vibration issues persisted, being most evident at idle and at cruising engine speeds of 950 rpm. As a result of the issues, the Tornado had a continuous rating of only 585 hp (436 kW) at 890 rpm and a maximum of 650 hp (485 kw) at 935 rpm. Utilizing the permissible speed range, the engine was run 225 hours non-stop without issues. Fuel consumption was .385-.40 lb/hp/hr (234-243 g/kW/h).

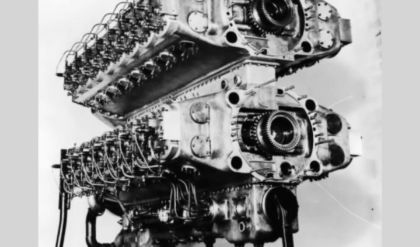

On the R101, two of the Tornado engines were to be fitted with reversible pitch propellers to aid maneuvering, but these propellers failed during testing. As a stopgap measure, one engine was fitted with a propeller of reverse pitch; this would mean that only four engines provided forward thrust, and one engine was used as a reversing motor only. Later, two of the engines were fitted with a reversing gear that allowed them to be stopped and then run in the opposite direction, but all five engines could be used for forward thrust.

Beardmore Tornado in the engine car for the R101 airship. The propeller flange on the right was at the rear of the car. Note the varying lengths of exhaust pipes on the far side. Also, the intake ports have changed from circular, as seen on the Mark I engine, to oblong. In the front of the car (left side of image) was a generator.

Each Tornado engine was installed in an enclosed engine car on the R101. The cars hung below the airship and allowed for easy servicing and maintenance of the engines while on the ground or in flight. The cars could also be removed and replaced as a unit. Each car contained the Tornado’s starting motor. As installed on the R101, each pod weighed a portly 8,580 lb (3,892 kg).

Reportedly, the Tornado engines were installed on the R101 by 24 September 1929. Its first flight, which was over 5 hours, was on 14 October. After a series of flights, the R101 was found to be very overweight, and modifications to lighten the airship started on 30 November. Some of the modifications were to increase the size of the gas bags in the R101, despite the possibility that they could rub on the airship’s framework. An additional gas bag was installed in a new midsection of the R101. While the ship was down, a Tornado engine in a complete engine car was test run the equivalent flight time from London to Karachi, British India (now Pakistan) and back without any issues. The R101 returned to the air in June 1930 but still experienced issues: hydrogen leaked from the gas bags, and its outer skin covering had deteriorated and was prone to ripping. The R101 was down for repairs again.

The 777 ft (237 m) long R101 airship moored at RAF Cardington. Four of the five Tornado engine cars can clearly be seen. The one at the rear of the R101 also provided airflow over the rudder to aid maneuvering.

Following the repairs, the R101 made its first trial flight (of almost 17 hours) on 1 October 1930. This would be the airship’s last flight before setting off for Karachi on 4 October. The R101’s spare Tornado engine had been shipped ahead, in case it was needed. On the evening of 4 October, the R101 started its voyage. About eight hours later, the airship was caught in a storm over Beauvais, France. The airship began to nose down out of control. It impacted the French countryside and burst into flames, ultimately killing 48 of the 54 people on board.

A board of inquiry investigated the R101 tragedy to determine the probable cause. They believed that skin in the front of the airship ripped during the storm and caused a gas bag to rupture. With the hydrogen escaping, the nose of the R101 became heavy and dropped toward the ground; the airship was doomed. Despite being overweight and under-powered, the Tornado engines did not play a role in the airship’s demise. After the R101’s crash, the R100 was grounded and later scrapped even though it had operated without major issues, even completing a flight to Canada and back. Eventually, the accident put an end to Britain’s airship programs. One of the R101’s Tornado engines was salvaged and returned to the United Kingdom. It is currently on display as a partial cutaway at the Science Museum in London.

During World War II, a British soldier deployed in India stumbled upon the last of the Tornado engines. The spare engine that had been shipped ahead of the R101 had been installed in a train and pressed into service. Harkening back to its origins, apparently the Tornado made a good diesel locomotive engine.

The salvaged Beardmore Tornado engine from R101 airship. This engine is currently on display at the Science Museum in London. (Andy Dingley image via Wikimedia Commons)