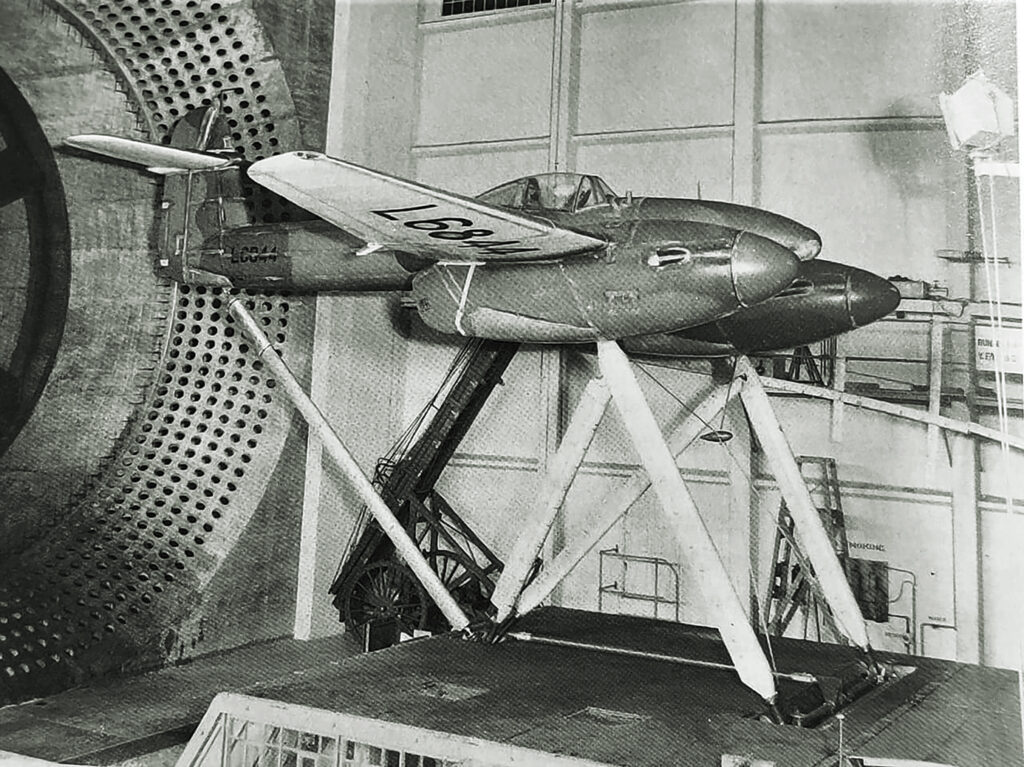

It could have been a game-changer. The twin-engine, single-seat Westland Whirlwind, produced by a small company in southwest England, looked like a formidably potent weapon. The four 20mm cannon packed close together in the nose could take out a tank when nothing else flying could. It was also innovative. It had a bubble canopy, intakes in the wing’s leading edges, slats and Fowler flaps. It had a slab-sided fuselage over the wing, which was the ultimate solution to high-speed interference drag. When it first flew on October 11, 1938, the Whirlwind was arguably the fastest, most heavily armed fighter in the world.

Today, very few have heard of it. Westland built only 114 and the Royal Air Force sent the Whirlwind to Scotland to keep it out of the fighting during the Battle of Britain. It has often been labeled a failure. The reason given has always been the inability of its two 885-hp Rolls-Royce Peregrine engines to deliver speed at altitude.

The RAF’s testing program had given the aircraft a clean bill of health and a ceiling of 31,000 feet. However, as the first trickle of aircraft began to arrive with No. 25 and 263 Squadrons in 1940, service pilots began to question why the altitude performance wasn’t what it was during test flights. “It must be emphasised…that the performance of the Whirlwind above 20,000 feet falls off rapidly, and it is considered that above 25,000 feet its fighting qualities are very poor,” read one report. “The maximum height so far attained is 27,000 feet but on every occasion that a height test has been carried out there has been a minor defect, either in airscrew revolutions or in lack of boost pressure.”

The reply from the technical director of the test facility was straightforward—the aircraft in service were identical in all respects to the one tested, so the difference couldn’t be explained. The Whirlwind’s own designer, the eccentric W.E.W. “Teddy” Petter, blamed a fall-off in boost pressures delivered by the superchargers with height at “twice the rate anticipated.” By doing so, he placed the blame with the Rolls-Royce engines division.

The key difference between the tested prototype and the Whirlwinds in service was considered too minor to be worth commenting on officially at the time. It was the propeller. The prototype sent by Westland to the RAF had a one-off Rotol propeller design, not the de Havilland/Hamilton propellers that the production Whirlwinds received.

The metal blades of the de Havilland props were very thick for a high-performance fighter—they had a 9.6% thickness-to-chord ratio (at the standard measuring point 70% of the way out along the blade). For comparison, the Spitfire’s blades were similar, but at 7.6% the ratio was smaller. This wouldn’t matter at low speed, but in a climb at 15,000 feet the tip of the Whirlwind’s propeller moved at Mach 0.72. Here, the difference between the 6% ratio at the tip of the Spitfire’s prop and the 8% of the Whirlwind’s was literally critical, meaning the tips approached the speed of sound. But an even bigger problem came with the combination of a thick profile blade with a constant speed mechanism.

That mechanism was—and remains—a widely used solution for keeping an engine turning at the optimum speed to produce maximum horsepower, whether the aircraft is moving slowly or at its maximum speed. This is done by changing the “bite”—the angle of attack of the propeller blades. Increasing the blades’ angle of attack increases the drag and thus the braking effect on the engine. To maintain a constant RPM at varying speeds, the pilot controls the propeller’s pitch. A constant speed unit automates the process, with the pilot setting the desired RPM. The unit senses if shaft speed drops, and “fines” the blades appropriately by changing pitch. The Whirlwind had two de Havilland constant speed units under its sleek cowls.

Dynamic tests in 1938 showed that the massive onset of drag above critical Mach would cause the blades to pivot—reduce pitch—as the constant speed mechanism hunted for a lower-drag condition to maintain RPM. Mach number lowers with altitude, so as the Whirlwind climbed at a constant RPM, relative Mach over the blades increased. Moving steadily inwards, more of the blade “went critical” as the phenomenon of compressibility created shock waves, drag rose exponentially and the blade turned farther to compensate.

This could reduce the blade angle of attack beyond zero. Add in any amount of aircraft pitch (and in a climb at altitude the aircraft would be pitched several degrees higher than line-of-flight) and shock waves would run up and down the blades as they spun. Wildly varying dynamic pressures would pass into the ram-air intakes, which sit immediately behind the blades. The intermittently windmilling prop would produce fluctuating boost pressures on top of reduced RPM.

It was very shortly after receiving the report about “very poor” fighting qualities above 25,000 feet that Sir Hugh Dowding, the head of Fighter Command, made his decision to keep the Whirlwind away from any fighting in the south, sealing its reputation as the fighter that missed the Battle of Britain. “The limiting factor in the present fighting against ME 109s in the South of England is the performance, manoeuvrability and climb at high altitudes, and a difference in service ceiling of 2,000 feet is a very important advantage,” Dowding said. “It therefore seems to me quite wrong to introduce at the present time a fighter whose effective ceiling is 25,000 feet.”

Ultimately the cancellation of the Whirlwind in November 1940 was an economic decision. Rolls needed to concentrate on developing and producing Merlin and Griffon engines, and it was never too sensible (“extravagant,” as Dowding called it) to produce a fighter that required two engines to do what another might with one.

Contrary to popular belief, the Whirlwind went on to serve successfully for another three years, unaltered, in the role of a low-level strike aircraft over the English Channel and occupied France. More than one veteran has commented that they felt comfortable taking on Fw-190s in 1943 in the unmodified, undeveloped 1938 Whirlwind. Down low nothing could catch a Whirlwind. It was maneuverable, practically viceless and its pilots learned to love it.

There is little doubt that the thick blades with the wrong airfoil section held the Whirlwind back. By the time fighters were doing 420 mph and higher at altitude with two-stage superchargers and blade tip speeds of over Mach 1, the blades were very thin and had profiles that had been developed to negate compressibility completely. But by then the time had passed for the Whirlwind and the much-maligned Peregrines that powered it.

Fascinating & informative article. Thank you.