The German engine manufacturer Deutz AG can trace its roots back to the inventor of the four-stroke internal combustion engine, Nicolaus Otto. Gottlieb Daimler, Wilhelm Maybach, Rudolf Diesel, Robert Bosch, and Ettore Bugatti all worked for progenitors of Deutz at one time or another. In 1935, the company, then known as Humboldt-Deutz, was commissioned by the RLM (Reichsluftfahrtministerium or German Ministry of Aviation) to develop experimental two-stroke diesel engines.

The eight-cylinder KHD Dz 700 two-stroke diesel before the engine was returned to Germany. Note the manifolds in between the cylinders for the incoming fresh air and the exhaust ports on the front of the cylinders. (Joe Gertler/Memaerobilia image)

This new line of engines was, in part, to compete with Junkers’ Jumo two-stroke diesels. The Junkers engines used two opposed pistons in the same cylinder which moved toward each other for the compression stroke. These pistons also covered and uncovered the intake and exhaust ports. Dr. Ing (Engineer) Adolf Schnürle, who was employed by Humboldt-Deutz, had earlier developed a new method for two-stroke cylinder porting. Schnürle’s method became known as Schnürle porting (or Schnuerle porting) and used reverse loop scavenging. In the cylinder, the exhaust port was positioned in between and slightly higher than the two intake ports. When the piston uncovered the ports, the charge of fresh air would enter and flow to the back of the cylinder. The fresh air would then reverse direction and push all remaining gases out the exhaust port. Being higher on the cylinder, the exhaust port was uncovered longer than the intake ports; this allowed the incoming fresh air charge to fully evacuate the exhaust gases from the cylinder.

Schnürle was put in charge of the new Humboldt-Deutz diesel engine project. Preliminary tests were conducted in Cologne, Germany on small single-cylinder and two-cylinder engines. In 1937, the Dz 700 was built. It was an eight-cylinder, two-stroke, air-cooled, diesel engine. The engine had a 3.15 in (80 mm) bore and a 3.94 in (100 mm) stroke, giving a total displacement of 245 cu in (4.0 L). The Dz 700 produced 158 hp (118 kW) at 2,800 rpm. The Dz 700 had a diameter of around 38 in (1 m) and weighed only around 120 lb (55 kg). A blower (weak supercharger) forced air through manifolds in between and then into the cylinders. Utilizing Schnürle porting, the two intake ports were positioned slightly lower in the cylinder than the two exhaust ports, and all were covered and uncovered by the piston.

The 16-cylinder KHD Dz 710 two-stroke diesel. Note the blower at the end of the engine with the coolant pump below and the fuel injection pumps under the engine.

In 1938, a six-cylinder engine was designed for use in training aircraft. A merger occurred in 1939, and the company became Klöckner-Humboldt-Deutz (KHD). The diesel engine projects were relocated to Oberursel, Germany. Shortly after, development of the six-cylinder engine and the Dz 700, which was then under tests, was abandoned. With the start of World War II, the RLM was interested in engines of higher power.

In 1939, Schnürle began work on the Dz 710—a 16-cylinder, liquid-cooled, engine. The original design was a fuel injected, spark ignition engine, but the design was developed into a two-stroke diesel. The Dz 710 was a horizontally opposed (or boxer/flat) engine with two banks of eight cylinders. Again, the cylinders were equipped with Schnürle’s reverse loop scavenge porting, but the system was doubled with four intake ports and two exhaust ports for each cylinder. The intake ports were 2.02 in (51.2 mm) tall and the exhaust ports were 2.65 in (67.2 mm) tall. Intake air came through a blower geared to the crankshaft at the rear of the engine that charged the air to 7.4 psi (.51 bar). The air then flowed through passageways into both sides of the cylinders. Exhaust gases were expelled both above and below the cylinder banks.

The horizontally opposed 16-cylinder KHD Dz 710 engine on a test stand in Oberursel, Germany. Note the exhaust pipes both above and below the cylinder bank.

The Dz 710 had a bore and stroke of 6.30 in (160 mm), giving a total displacement of 3,141 cu in (51.5 L). Direct fuel injection at 400 psi (27.58 bar) was used, and the compression ratio was 15 to 1. The engine also had a 0.4 to 1 propeller gear reduction. Recorded dimensions for the Dz 710 were a length of 94.5 in (2.40 m), a width of 53.1 in (1.35 m), and an estimated height of 39.4 in (1.00 m). The engine weighed 2,866 lb (1,300 kg).

Completed in 1943, the Dz 710 had a planned output of around 2,700 hp (2,013 kW), but development and testing was delayed by other war priorities; KHD was involved in the production of diesel truck engines. Two Dz 710 engines were built with a third partially completed. In 1944, a Dz 710 test engine achieved 2,360 hp (1,760 kW) at 2,700 rpm, and both engines had accumulated a total of about 150 hours of operation. A very good specific fuel consumption of 0.34 lb/hp/hr (207 g/kW/hr) was recorded at cruise power. However, the Dz 710 had trouble with its pistons and ultimately used a bolted steel plate piston crown. In addition, two crankshafts failed due to torsional vibrations.

A turbocharged version of the Dz 710 was planned with an estimated output of 3,060 hp (2,280 kW). Either a mockup or actual parts for the turbocharger installation were built, but it is not clear if this engine ran. The turbocharger would have increased the intake air pressure to 23.5 psi (1.6 bar).

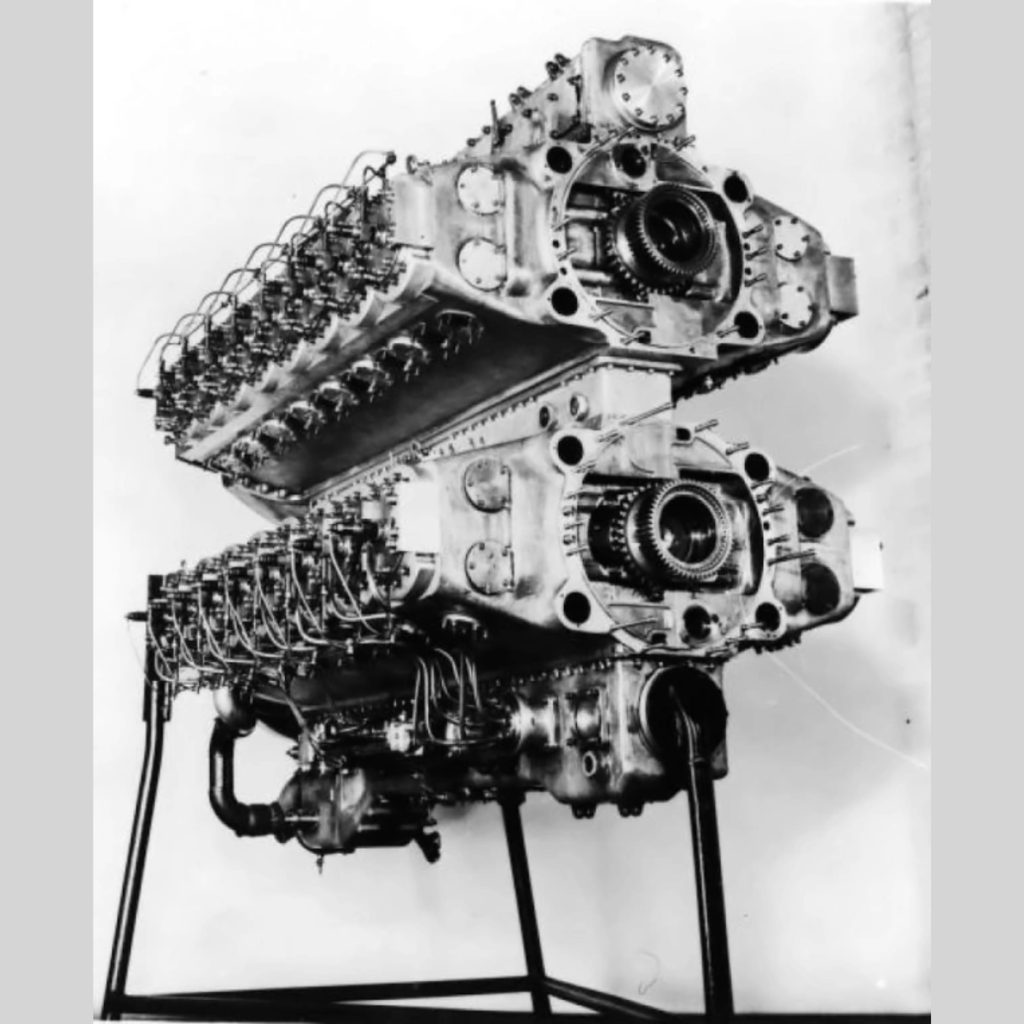

The 32-cylinder KHD Dz 720 was quite literally two Dz 710 stacked on top of each other with the upper engine inverted. This arrangement formed an H-32 engine with an estimated max output of 5,900 hp (4,400 kW) with turbocharging.

By 1944, in the quest for more power, the two Dz 710 engines were stacked to form the Dz 720 (KHD actually referred to this engine as the Dz 710 P2). This 32-cylinder H engine had a displacement of 6,282 cu in (102.9 L). The turbocharged H-32 had an estimated output of 5,900 hp (4,400 kW) while the engine blower version was forecasted to produce 4,600 hp (3,430 kW). With a .3125 to 1 gear reduction for a single propeller, the engine was originally intended for use in large, long-range aircraft. However, the German Navy showed interest in utilizing it for high-speed boats. While the Dz 720 should have similar length and width as the Dz 710, the actual recorded dimensions were a length of 106.3 in (2.70 m), a width of 65.0 in (1.65 m), and an estimated height of 78.7 in (2.00 m). Perhaps the extra 11.8 in (0.3 m) length of the Dz 720 incorporated a combining gear converting the two Dz 710 power sections to a single output shaft. Dz 720’s weight was documented as 5,732 lb (2,600 kg) with engine blowers and 6,393 lb (2,900 kg) for the turbocharged version.

Schnürle was very committed to the Dz 710 engine. At the end of World War II, he made it clear to the Army Air Force that he was willing to go to the United States with his engines and continue their research and development. While the Dz 700 and the two Dz 710 engines were taken to the United States, it was not for Schnürle to continue their development. The ultimate disposition of the Dz 710 engines has not been found, but the eight-cylinder Dz 700 radial engine ended up in a private collection in Florida. Around 1998, it was purchased by a private collector in Germany and returned to that country.

Side view of the KHD Dz 720. Note the spacer placed in between the Dz 710 power sections to provide clearance for the blowers on the left of the image. The Dz 720 was a very tall engine which would have made installation in an aircraft difficult.